- Abrasion

- Colour Fastness

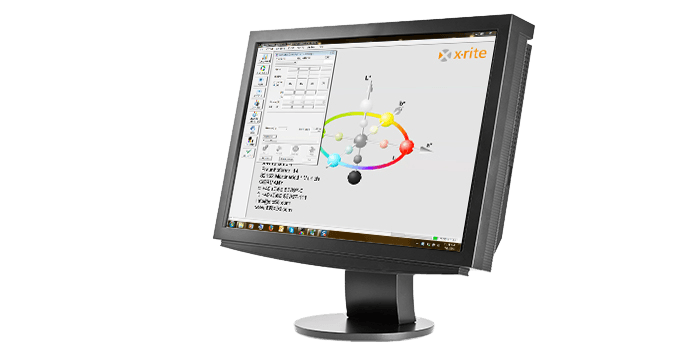

- Colour Matching, Quality Control & Formulations

- Comfort & Performance

- Close Control Conditioning Systems

- Dyeing & Finishing

- Fiber

- Flammability

- General Equipment

- Grading

- Lab Accessories

- Lab Dyeing & Dispensing

- Light & Weather Fastness Testing Equipment

- Metal Detectors

- Mullen Testers

- Nonwovens

- Pantone Color Matching Solutions

- Personal Protective Equipment (PPE)

- Pilling & Snagging

- Remote Access

- Safety

- Sample Preparation

- Strength

- Tensile Testers

- Visual Assessment

- Washing & Laundering

- Water & Vapour Resistance

- Yarn

- Abrasion

- Colour Fastness

- Colour Matching, Quality Control & Formulations

- Comfort & Performance

- Close Control Conditioning Systems

- Dyeing & Finishing

- Fiber

- Flammability

- General Equipment

- Grading

- Lab Accessories

- Lab Dyeing & Dispensing

- Light & Weather Fastness Testing Equipment

- Metal Detectors

- Mullen Testers

- Nonwovens

- Pantone Color Matching Solutions

- Personal Protective Equipment (PPE)

- Pilling & Snagging

- Remote Access

- Safety

- Sample Preparation

- Strength

- Tensile Testers

- Visual Assessment

- Washing & Laundering

- Water & Vapour Resistance

- Yarn

-

Our Products

- Abrasion

- Colour Fastness

- Colour Matching, Quality Control & Formulations

- Comfort & Performance

- Close Control Conditioning Systems

- Dyeing & Finishing

- Fiber

- Flammability

- General Equipment

- Grading

- Lab Accessories

- Lab Dyeing & Dispensing

- Light & Weather Fastness Testing Equipment

- Metal Detectors

- Mullen Testers

- Nonwovens

- Pantone Color Matching Solutions

- Personal Protective Equipment (PPE)

- Pilling & Snagging

- Remote Access

- Safety

- Sample Preparation

- Strength

- Tensile Testers

- Visual Assessment

- Washing & Laundering

- Water & Vapour Resistance

- Yarn

- Abrasion

- Colour Fastness

- Colour Matching, Quality Control & Formulations

- Comfort & Performance

- Close Control Conditioning Systems

- Dyeing & Finishing

- Fiber

- Flammability

- General Equipment

- Grading

- Lab Accessories

- Lab Dyeing & Dispensing

- Light & Weather Fastness Testing Equipment

- Metal Detectors

- Mullen Testers

- Nonwovens

- Pantone Color Matching Solutions

- Personal Protective Equipment (PPE)

- Pilling & Snagging

- Remote Access

- Safety

- Sample Preparation

- Strength

- Tensile Testers

- Visual Assessment

- Washing & Laundering

- Water & Vapour Resistance

- Yarn

-

Industry

-

Our Brands