FDA 21 Part 11 compliant

The THS/21ET Metal Detector Series is a high-sensitivity, high-precision measuring instrument. The data relating to each detection and ejection are stored in an events memory and certify production quality, the inspection itself and programming operations, as well as the periodic functional test phases using standard test samples.

FDA Code Title 21 Part 11 prescribes rigorous criteria for access to programming and computer data protection which have been fully adopted in the THS/21ET Series firmware.

The requirements regarding Security, Integrity and Traceability are therefore satisfied.

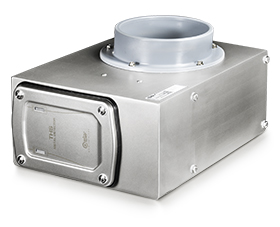

THS/G21ET-F series with Reduced Metal Free Zone for limited space installations, while maintaining optimal detection of all metals.

Exclusive auto-learn system

The THS/21ET Series employs an exclusive Auto-Learn system for food products which provides simultaneous maximum sensitivity to all metals starting from a single learning transit.

The system allows optimization of the detection sensitivity to all metals with the maximum speed and precision, equivalent to hundreds of conventional learning transits: these results in high levels of precision and efficiency.

Real-time embedded self-calibration control

The Self-Calibration control allows maximum repeatability and performance consistency over time and with environmental changes.

By means of specific signals sent to the transmission and reception chain of the Metal Detector, constant monitoring of the detection characteristics is carried out, with consequent constant compensation for any variations caused by environmental factors.

The result is system stability and consistency in detection performance and product effect neutralization.

Automatic verification of the installation quality and environmental compatibility

THS/21ET Series introduces new tools for the installation and maintenance technicians which allow them to measure the environmental compatibility of the Metal Detector.

The measurements include general mechanical and electromagnetic environmental compatibility, specific electromagnetic compatibility and the automatic examination of the degree of metal interference from the conveyor belt.

This latter function becomes even more important when the high level of sensitivity of the THS/21ET Metal Detector Series is taken into consideration.

Increases in productivity and cost savings

- Reduced product waste

- Fewer operator interventions

- Fewer product acquisition procedures

- Reduction in line stoppages

- No periodic calibration

Key features

- Industrial rate design

- Easy to read, high-contrast graphic display

- Rugged, antivandalic stainless steel keyboard

- Large Product Memory: 250 entries with easy alphabetical sorting and pattern matching

THS PRODUCTION 4.0

The THS Production 4.0 software provides acquisition and report capability for THS 21 Metal Detection Systems.

Smart factory

- CEIA-ERP API interface for communication to the factory management software (Microsoft Dynamics NAV, SAP, ORACLE ERP)

- OPC-UA protocol API for Metal Detector Monitor and Control

- Connection to an External Database and Definition of a Programmable Block of SQL Instructions for each Metal Detector Event

- Compatible with standard SCADA Systems

- E-mail sender for Metal Detector events

- Integrated Web-Server Appliance for real-time monitoring for HMI and touch panel

Predictive maintenance

- Data Inspector Tool for signal and production analysis (enhanced option)

- Early Metal Explosion identification

THS PRODUCTION 4.0 highlights

- Connects and Acquires Data from Multiple THS Detectors via wired or wireless LAN (requires IXC module)

- Enables Data Base Management and Back-Up of Metal Detector events

- Report Data Exportable in HTML, CSV and PDF formats

- Provides User Authentication and Manages Electronic Signatures and Records

- Allows Data Integrity and Operator Auditing

- FDA Requirements Compliant, Title 21 of the Code of Federal Regulations (CFR)

- High performance 64-bit database that handles more than 500 millions events

Network communication

The Metal Detector can be linked to an Ethernet network (optional IXC module required).

In association with the THS Production Plus Software it enables remote management of production, collection of all technical and operational events, generation of statistical and traceability reports in compliance with FDA 21 CFR part 11 requirements.

MD-SCOPE

Software Diagnostic Package complete with connecting cable and hardware key:

- Remote programming

- Input/Output signals

- Detected and alarm signals

- Oscilloscope functionalities

BT connectivity

In the THS/21 Series, local connection to the maintenance technician’s computer no longer requires physical access to the interior of the detector or the use of unwieldy connection cables.

The BT connection can be used for programming, monitoring of the signals via the CEIA MD-Scope program and the transfer of the data contained in the Metal Detector’s events memory.

AUTOTEST and AUTO-QC™ TEST functions

Industrial Metal Detectors for food application are usually equipped with basic diagnostic functions based on their emitter/receiver signals monitoring.

This type of diagnosis is not able to detect aging as well as thermal drift and other sources of minor deviations. Any of the above may result on a sensitivity reduction that could lead to non-detection of metal contamination.

THS/21ET metal detectors are natively equipped with an advanced AUTOTEST function ensuring the following features:

- Continuous background real-time monitoring and stabilization of the amplitude and phase response for each working frequency

- Continuous compensation of environmental and age-related changes

- Immediate alerting in case of permanent out of standard conditions

In addition to the AUTOTEST function, THS/21ET and THS/ET-3F detectors can be programmed so that periodic verifications of the calibration are carried out automatically. This feature is called AUTO-QC™ TEST.

- The AUTO-QC TEST allows the manual verification of calibration by the operator to be reduced or eliminated

- The METAL DETECTOR provides a programmable output that can be connected to the conveyor line stop during the AUTO-QC test to avoid product ejection and waste during automatic test

- CEIA AUTO-QC TEST provides an effective calibration check along with a programmable 0 ÷ 100 % reduction of the manual verifications, resulting in a corresponding reduction of: Labour cost; Accidental product contamination; Product waste

General characteristics

- High-contrast OLED display: Graphical, 128×64 pixels

- Programming keyboard, in stainless steel: 4 keys

- Metal detection sensitivity: High

- Display of the signal level by means of bar graph

- Autolearn and automatic tracking of the product effect

- Complies with HACCP and GMP criteria

- Metallic structures in AISI316. Parts in contact with the product in plastic materials, certified for food use, according to FDA and

- USDA specifications

Supply

- Control Power Box

- Mains voltage: 100-240 VAC

- Frequency and phase: 50/60 Hz – single phase

- Full load current (FLA): 2.2 A

- Conveyor Control System

- Mains voltage: 115V version: 100÷120 VAC / 230V version: 200÷240 VAC

- Frequency 50/60 Hz – single phase

- Full load current (FLA): 115V version: 11.8 A / 230V version: 12.9 A

- Maximum power of the three-phase pilotable motor: 115V version: 0.37 kW (0.5 hp) / 230V version: 0.75 kW (1 hp)

- Small-size power supply card

- Power supply voltage: 24 Vdc: 2.5A max.

Data management

Management of electronic production data and electronic signatures compliant with the requirements indicated by CFR 21, Part 11

- Data security

- Data integrity

- Data traceability

Data storage

- Max number of Products: 250

- Max number of Events: 1000 (100,000 with IXC )

I/O interfaces

- RS232 and auxiliary RS232 serial ports: Built-in

- BT Wireless interface: Built-in (v2.1, Class 2)

- Serial port for barcode reader (optional)

- IXC Network card (optional) with built-in Web Server

- Wi-Fi: On USB key; Wireless standard: IEE 802.11 b/g/n; Frequency: 2.400-2.4835 GHz; WPA2 security; Max range: up to 20m in open areas, subject to limitations

- Ethernet: 2 ports 10/100 baseT; IP Protocol: static/DHCP

- USB: V2.0 (only for data storage on USB memory devices, FAT32 formatted)

- Field Bus: Ethernet/IP (optional)

Protection degree

IP65 (On UL versions, the Control Power Box and Conveyor Control System have a type 4X-12 certified degree of protection)

Environmental conditions

- Temperature

- Operating -10°C to +55°C (14°F to 131°F) (CE version) / +5°C to +40°C (41°F to 104°F) (UL508A version)

- Storage -40°C to +70°C (-40°F to 158°F) – for short periods, not more than 24h

- Relative humidity

- Operating 5% ÷ 90%, non-condensing

- Storage 5% ÷ 90%, non-condensing